How Accurate Is a Laser Alignment Tool?

In industrial settings, precise alignment of machinery components, especially shafts, is critical for optimal performance and longevity. Misalignment can lead to excessive vibration, premature wear, and costly breakdowns. Laser alignment tools have become a popular solution due to their ability to provide highly accurate measurements. But just how accurate are these tools? Let’s explore in detail.

What Is a Laser Alignment Tool?

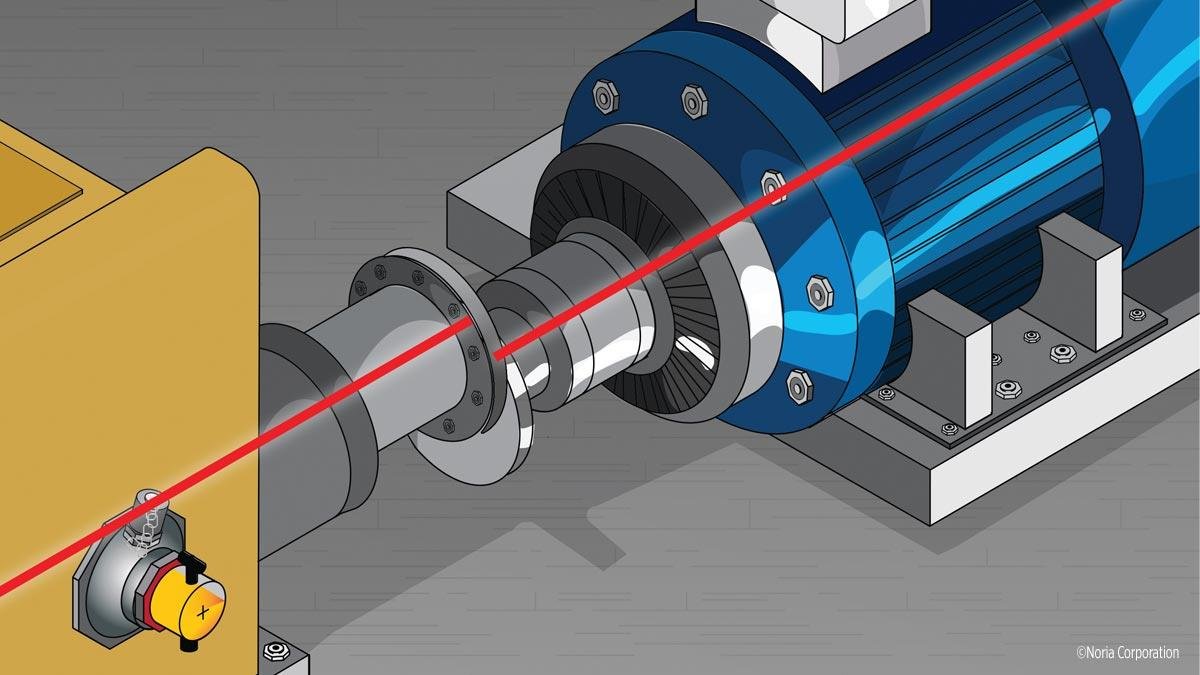

A laser alignment tool uses laser technology to measure and align two or more machine components, typically shafts. This technology replaces traditional methods such as dial indicators or straightedges, which can be less precise and time-consuming.

A typical laser alignment system consists of:

Laser source that emits a straight beam

Target sensor that detects the laser beam and measures deviation

Specialized software that calculates and displays alignment data in real-time

Accuracy Levels of Laser Alignment Tools

The accuracy of laser alignment tools depends on the technology and quality of the device. Generally:

Industrial-grade laser alignment tools can achieve accuracy within ±0.001 inches (±0.025 mm) for shaft alignment.

Premium models with advanced sensors and software can reach even higher precision, up to ±0.0001 inches (±0.0025 mm) or better.

To put this into perspective, even a 0.01 mm misalignment can significantly affect machine performance and bearing life.

Factors Affecting Laser Alignment Accuracy

Although laser alignment tools are highly precise, several factors can influence their accuracy:

1. Quality and Calibration of the Tool

Regular calibration is essential to maintain valid measurement results. A worn or damaged tool can reduce precision.

2. Working Environment

Vibrations from nearby operating machinery can interfere with sensors

Extreme temperatures and humidity can affect electronic components

Dust and dirt can obstruct the laser beam

3. User Technique

Proper setup and measurement procedure are crucial, including:

Correctly mounting the tool on the shafts

Ensuring the laser and sensor are aligned without obstruction

Taking multiple measurements for consistency

4. Measurement Distance

Longer distances between the laser source and sensor can increase potential errors, although modern tools compensate for this.

Advantages of Using Laser Alignment Tools

High precision: Ensures very accurate alignment results

Time efficiency: Faster than manual methods

Reduced downtime: Machines run smoother with fewer breakdowns

Cost savings: Less wear and maintenance costs

Tips for Choosing and Using a Laser Alignment Tool

Select reputable brands with good after-sales support and warranty

Choose tools with user-friendly software for easy data interpretation

Perform regular calibration as recommended by the manufacturer

Train technicians to use the tool correctly

Use tools suited to your machine size and application needs